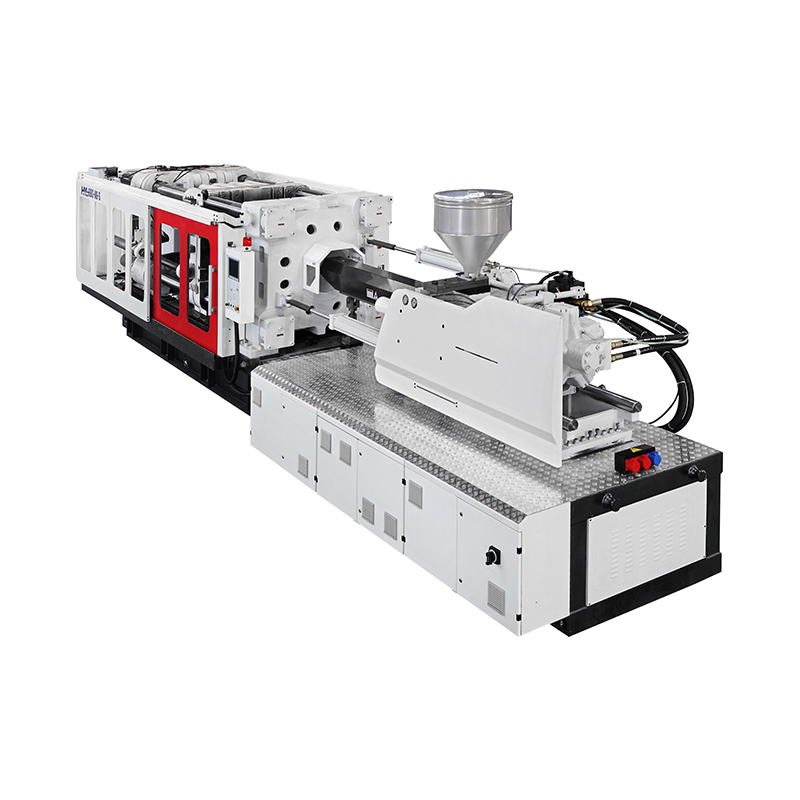

2019 China New Design Servo Pump Injection Moulding Machine - AY110 100T Plastic Injection Moulding Machine – Mega

2019 China New Design Servo Pump Injection Moulding Machine - AY110 100T Plastic Injection Moulding Machine – Mega Detail:

Machine Technical Date:

| Injection Unit | ||||

| Shot volume | cm3 |

145 |

183 |

226 |

| Shot weight (PS) | g |

132 |

167 |

206 |

| Oz |

4.7 |

5.9 |

7.3 |

|

| Screw diameter | mm |

32 |

36 |

40 |

| Injection pressure | Mpa |

240 |

189 |

153 |

| Injection rate | g/sec |

88 |

111 |

137 |

| Screw L/D ratio | L/D |

22.5 |

20 |

18 |

| Screw stroke | mm |

180 |

||

| Screw speed (stepless) | Rpm |

0 ~ 230 |

||

| Clamping Unit | ||||

| Clamping force | Ton |

110 |

||

| Opening stroke | mm |

350 |

||

| Platen size | mm |

530 x 480 |

||

| Space between tie bars | mm |

420 x 370 |

||

| Max. daylight | mm |

750 |

||

| Mold thickness (min-max) | mm |

150 ~ 400 |

||

| Hydraulic ejector stroke | mm |

110 |

||

| Hydraulic ejector force | Ton |

4.5 |

||

| Ejector pin | pcs |

5 |

||

| Hydraulic Unit | ||||

| Hydraulic system pressure | Mpa |

17.5 |

||

| Pump motor | kW |

11 |

||

| Servo driver power | kW |

15 |

||

| Heating capacity | kW |

7 |

||

| Number of temp control zones | pcs |

4 |

||

| General Data | ||||

| Oil tank capacity | L |

150 |

||

| Machine dimensions | m |

4.5 x 1.2 x 1.8 |

||

| Machine weight | Ton |

3.7 |

||

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for 2019 China New Design Servo Pump Injection Moulding Machine - AY110 100T Plastic Injection Moulding Machine – Mega , The product will supply to all over the world, such as: Provence, Jakarta, Provence, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us