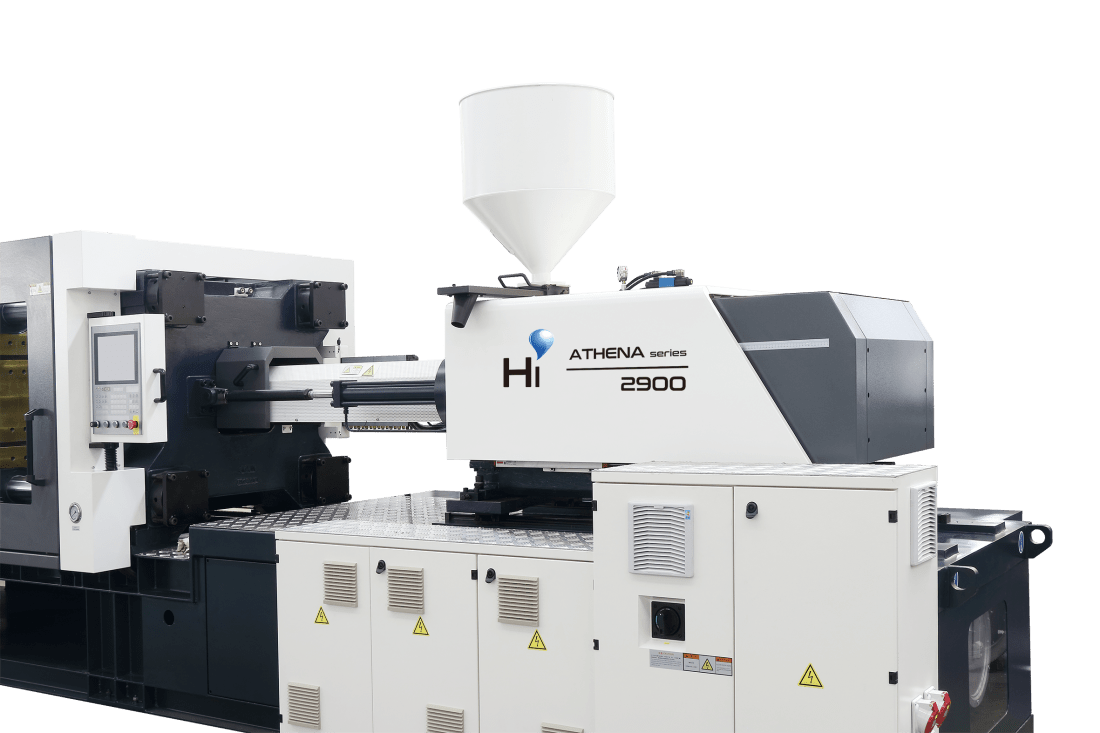

AT 110-S

Machine Technical Date:

| Injection Unit | ||||

| Screw diameter |

mm |

32 |

35 |

38 |

| Screw L:D |

L/D |

25 |

22.8 |

21 |

| Injection volume |

cm3 |

137 |

164 |

193 |

| Shot weight |

g |

125 |

149 |

175 |

| Injection rate |

g/s |

93 |

112 |

132 |

| Injection pressure |

bar |

2278 |

1904 |

1615 |

| Screw speed |

rpm |

220 |

||

| Clamping Unit | ||||

| Clamping Force |

kN |

1100 |

||

| Opening stroke |

mm |

360 |

||

| Space between tie bar |

mm |

420 x 370 |

||

| Max. mold height |

mm |

400 |

||

| Min. mold height |

mm |

150 |

||

| Ejector stroke |

mm |

100 |

||

| Ejector force |

kN |

38 |

||

| Others | ||||

| Max. system pressure |

MPa |

16 |

||

| Motor pump power |

KW |

15 |

||

| Heating capacity |

KW |

8.1 |

||

| Machine dimensions |

m |

4.25 x 1.17 x 1.6 |

||

| Oil tank capacity |

L |

200 |

||

| Machine weight |

t |

3.8 |

||

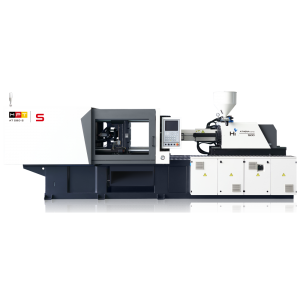

1. Dual cylinders structure injection unit, powerful and reliable.

2. Two layers linear guide rails and one piece type injection base, faster speed & better repeatability.

3. Dual carriage cylinder, highly improved injection precision and stability.

4. Standard with ceramic heaters, improved heating & heat preservation capacity.

5. Standard with material drop down chute, no harm to machine paint, improve production area clean.

6. Standard with nozzle purge guard, ensure a safer production.

7. No welding piping design, avoid oil leaking risks.

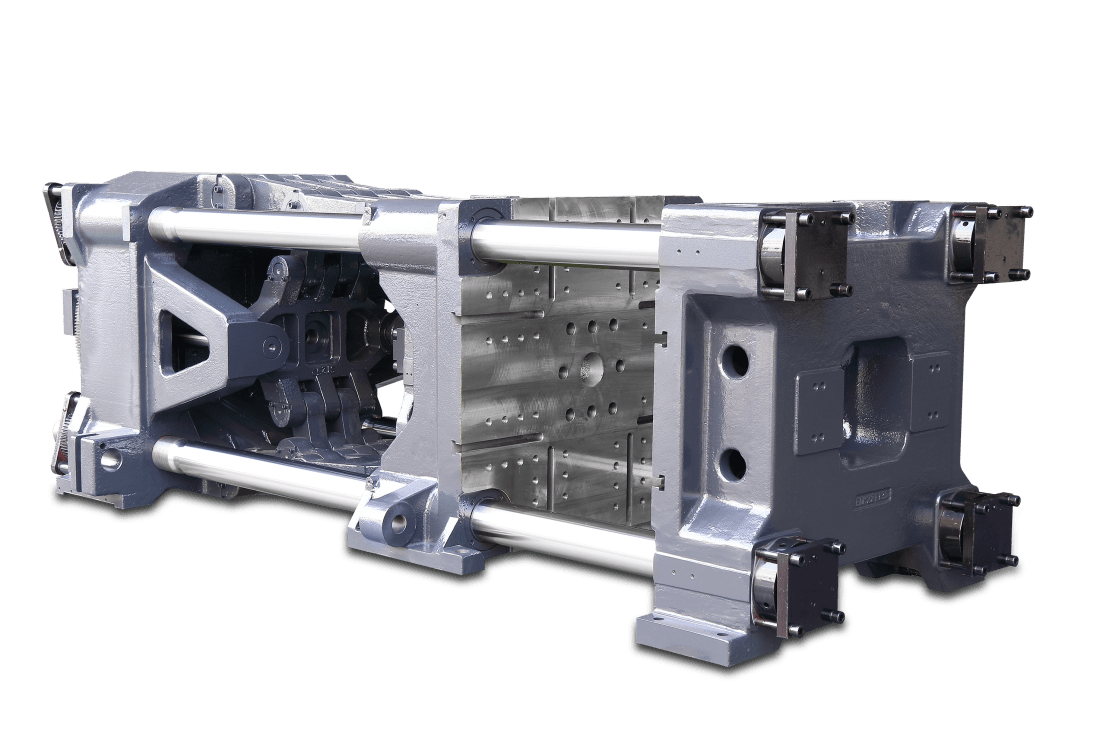

A. Larger tie-bar spare and opening stroke, more molds sizes are available.

B. High rigidity and reliable clamping unit, ensure our machines reliability.

C. Longer and stronger movable platen guide slider, highly improved the mold loading capacity and mold open & close precision.

D. Better designed mechanical structure and toggle system, faster cycle time, improve production efficiency.

E. T-SLOT is standard on full series, easy for mold installation.

F. European type ejector structure, larger space, convenient for maintenance.

G. Large reserved space for upgrade and retrofits.

H. Integrated & adjustment free mechanical safety, safer and more convenient.

1. Energy saving: standard with precision and energy saving servo power system, the output drive system is sensitively altered, according to the actual need of the plastic parts being produced, avoid energy waste. Depending on the plastic parts being produced and the material being processed, energy-saving ability can reach to 30%~80%.

2. Precision: Precise servo motor with precise internal gear pump, via a sensitive pressure sensor to feedback and become close-loop control, injection repeatability precision can reach to 3‰, highly improved product quality.

3. High speed: High response hydraulic circuit, high performance servo system, it requires only 0.05sec to reach the maximum power output, cycle time is substantially shortened, the efficiency is improved significantly.

4. Save water: Without overflow heating for servo system, much less cooling water required.

5. Environmental protection: Machine working quietly, low energy consumption; famous brand hydraulic hose, Germany DIN standard hydraulic pipe fitting with seal, G screw thread style plug, avoid oil pollution.

6. Stability: Cooperate with famous brands hydraulic suppliers, precise control force, speed and direction of hydraulic system, ensure machine’s precision, durability and stability.

7. Convenient: Dis-mountable oil tank, easy for hydraulic circuit maintenance, self-seal suction filter, reasonable placed hydraulic pipe fittings, maintenance will be easy and convenient.

8. Future-proofing : Modular designed hydraulic system, no matter function upgrade, or retrofit hydraulic system, our reserved installation position and space will make it so easy.

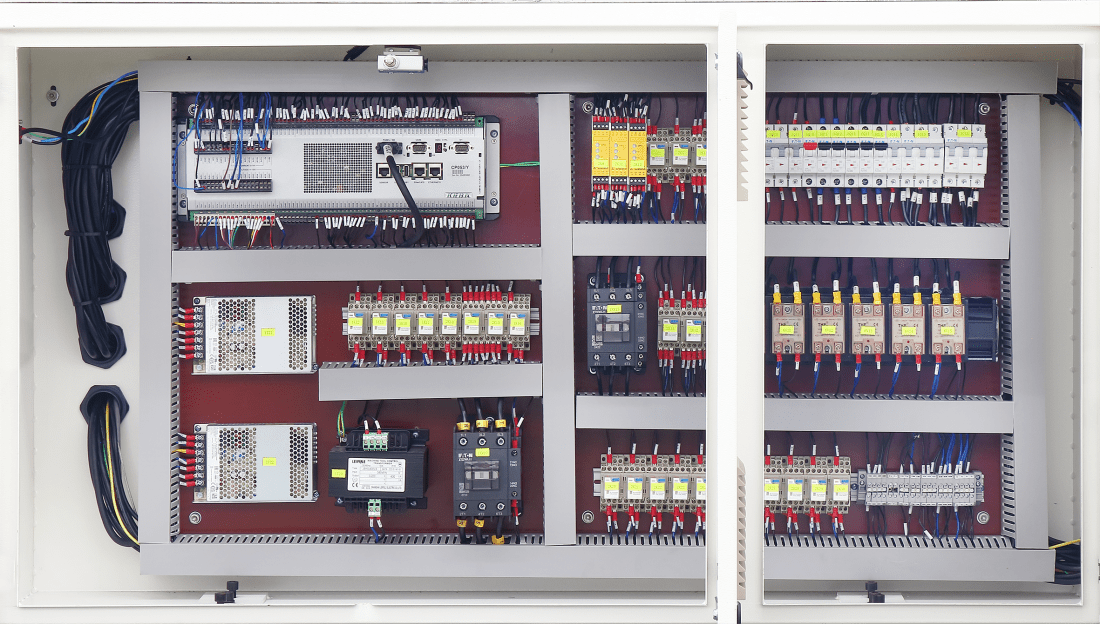

Fast response controller system is helpful to make high precision and fast cycle molding to be easier;

Highlights:

First class quality & wold-famous brands electrics hardware;

Thorough & stable software with easy operation interface;

Safer protection for electric circuit;

Modular designed cabinet design, easy for functions update.